Sections

A non-invisible image is referred to radiation system where the image is obtained without any visible radiation of the object. To get a satisfactory resolution from the image that is formed with the help of the invisible radiation, the image can be enhanced too. This highly developed technology was derived from the Bright Field Resolution Limited Technique. This technology works on the framework of axial-illumination that is constricted to visible light. The one important thing for this imaging is confocal microscopy.

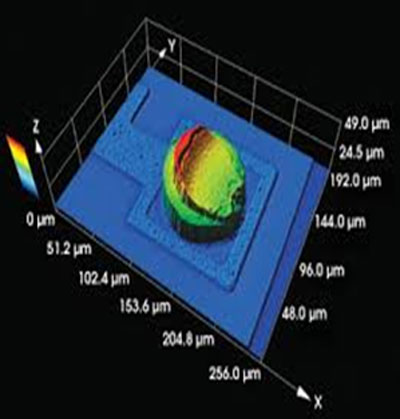

The Confocal microscopy tool is used to amplify the quality of the image by providing highly defined contrast and precise resolution to each and every part of the image. This brings a depth in the focus and allows the people to testify certain inside devices like the Micro Electrical Mechanical Systems. It is even reckoned that the demand of this imaging technique only took place because of its need in the field of MEMS, so that the industry can work is a proficient manner. This helped the technology too, as now this imaging technology could have an improved resolution and proved efficiency. And this was made possible through Near-IR and deep UV along with the amalgamation of Confocal microscopy.

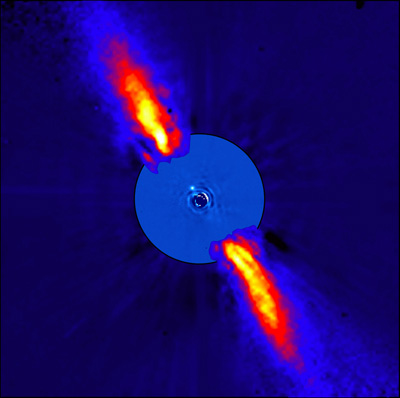

This imaging technique can even be embraced as infrared light, which is not visible to the human eyes as this light stands beyond the red light. When talking about the working of imagining that is not visible then Near-IR or Near Infrared is something that makes it all happen.

This has become one of the vital semiconductors for those manufacturers which widely use Silicon as their essential substrate. The important factor here that allows the working of such imaging is that silicon has a perfected capability to transmission with the near IR spectrum. The process or the initial working of this sort of imaging takes place by optimizing an optical system at a particular wavelength band, and now with the help of image analysis software that allows the system to create and measure the image in just a few seconds.

For further rooting the capability of the IR is retrofitted and this is done through the microscopic systems. The retrofitting technique is completed without removing a single component from the microscope. To achieve this, one thing should be noted that the microscope should be fine tuned and for optimizing the optics that are coated to bring the right transmission and contrast for the invisible wavelength.

The Near-IR which is a common equipment of this Imaging technique is widely used in the manufacturing of MEMS, to work out the wafer bonding and to view the interior of the device, which will allow the engineers to check whether the systems built in the MEMS without having to open the entire system. This definitely kills the chaos of opening and fixing the system from scratch and at the same time, it even saves time as within just a fraction of second one can discover whether the MEMS system is alright or not. The working of Near-IR on the MEMS is made possible only because of silicon.

Silicon is transparent and allows the working of near-IR wavelengths. The Near-IR trigger a fast conducive nondestructive check that inspects each and every part of the system can be measured and the entire checking process could be achieved in just a few minutes. This is truly beneficial for those Micro Electrical Mechanical Systems which are used in various apparatus, so that the developers can check these micro systems without actually opening each and every section of the micro system.

Since the demand of this technology is increasing with increasing time, this has led to several detailed research on this imaging system and soon, people will be able to witness bright resolution images and fine surface image in the near future. With the perfected tools and technology of geometrics the overall working of this imaging will be much more compact, so that the entire imaging system because much more affordable than it is today. This will make the entire imaging system quite economical and they will find a very useful place at every sector of Micro Electrical tools.

Sections