Sections

A solar cell is basically an electrical device that uses photovoltaic effect to convert sunlight energy into electricity. The photovoltaic effect can be defined as a phenomenon that generates voltage or current with the exposure of light in a material. On absorption of sunlight the electrons, that is part of valence band gets enough energy to jump into the conduction band and thereby becomes free.These electrons that is, highly excited electrons, diffuse and on reaching the junction, they are carried onto another material with the help of built-in potential. This movement generates electromotive force (emf) which converts a certain amount of light energy to electric energy. This is the simple understanding with solar cell and photovoltaic effect.

The layers so designed to form a solar cell is such that one layer is willing to lose electrons and other layer is ready to accept electrons. Thus N-type and P-type silicon layers are used to build a solar cell. Though there are electrons willing to move but there is a shortage of energy to make it free which is obtained by solar energy. When light falls, electrons starts to move in the same direction which provide electricity. When metal contacts are attached to two sides, there is a flow of electric current through external circuit. The obtained DC current is converted AC using inverter makes it usable for home purposes.

A set of solar cells that is being packaged and connected to form photovoltaic modules, that are electrically connected and placed on a structure for support is termed as solar panels. Solar panels are used for large scale generation of electricity for commercial and house-hold applications. DC output power for each module is checked under Standard Test Conditions (STC) and ranges between 100 to 320W. Multiple modules are required to obtain a larger amount of power.

Solar Panels play a major role for the efficient utilization of green energy. These solar panels are considered to be an environmentalist’s dream since they can produce limitless electricity from the sun with no air pollution or carbon dioxide emissions. To increase the dependence on solar energy, different types of solar panels are now made available in the market all over the world.

![]()

Polycrystalline Solar Panels were first introduced in the market in the year 1981. Through its arrival, it became one of the best options to obtain green energy. Now it is a common type and is good for residential installations. Multicrystalline, Multi- Silicon and Ribbon are the other popular names by which they are known in the market.

Polycrystalline solar panels are made from silicon offcuts, moulded together to form blocks and creates a cell made up of several bits of pure crystal. The solar cells present in the panel work together to gain energy from the sunlight and finally help in conversion. When individual crystals of the solar cells are considered, we can see that they are not perfectly aligned. Due to this misalignment, many losses occur at the joints, thereby making this solar panel less efficient. Generally, the Polycrystalline panels come up with 12-16% efficiency. Its common appearance is in the form of a blue solar panel with square cells. As an advantage, this panel has very little wasted space.

Today, wide range of manufacturers is available across the world in the production of polycrystalline solar panels. SunTech Power, BP SX (formerly Solarex), Canadian Solar, Tenesol, Jaiwei, Kyocera, Luxor, Mitsubishi Electric, , Schott, Quantum Solar, Sharp, Sunenergy, Trina Solar, Yingli and Yohkon are some of the common polycrystalline solar panel manufacturers. Most of them come up with inexpensive panels having a warranty of about 25 years.

Polycrystalline solar panels can be installed on building tops, rooftops, or stand-alone facilities using a solar panel mount. All the three main varieties of solar panel mounts like pole mounts, roof-ground mounts, and flush mounts can be used for its installation. While installing, place the panel in such a way that direct exposure to sunlight is maximum.

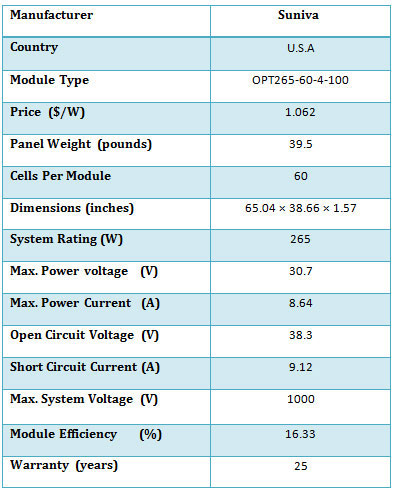

Table1:Specifications of a type of Polycrystalline Panels

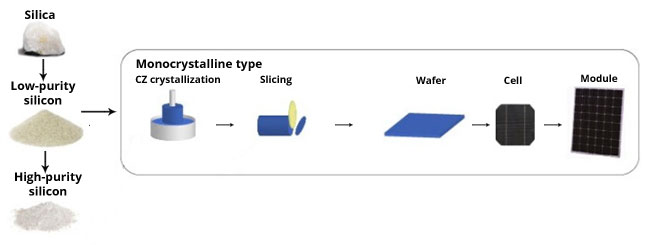

Monocrystalline solar panels have been the best choice for many years. They are among the oldest, most dependable and efficient solar panels to produce electricity from the sun. Each module in the solar panels is made from a single silicon crystal, and is more expensive, than the cheaper polycrystalline and thin-film panels. Mainly, the monocrystalline solar panels appear in black or iridescent blue color with rounded end solar cells and are good for domestic and industrial installations. Today in the market world, they are well known by the names ‘Mono Silicon’ or ‘Single Silicon’.

One of the features of this solar panels is that, each solar cell is aligned in one direction. Due to this feature, these solar panels can be extremely efficient when the sunlight falls at correct angles. Today, many monocrystalline solar panels manufacturers come up with solar panels having 15-20% efficiencies. While comparing with the polycrystalline solar panels, there is large amount of unused space and the size is small. More wattage per square foot, durability, lower installation cost, more electricity per sqm and long lifetime are the best features of these panels.

Today, SunPower (USA) is the most efficient monocrystallne solar panel manufacturer. They generally come up with panels having 22.5% efficiency. Other common manufacturers are Suntech Power, JA Solar, Transform Solar, Sanyo, Suniva etc. Almost all of these manufacturers ensure 25 years warranty and they suggest rigid mounting while installation.

| Table 2: Specifications of a type of Monocrystalline Panel | |

|

|

Amorphous Silicon

Usually Amorphous Silicon (a-Si) solar cells are used in small cell applications like pocket calculators. Its electrical output power is very low. But, recently some innovations made them more applicable one by using stacking technique. In this method several amorphous silicon solar layers are combined. By stacking solar cells into multiple layers, they can capture more sunlight and can produce more electricity.This technique gives more efficiency rate, typically around 6-8% more.

Usually Amorphous Silicon (a-Si) solar cells are used in small cell applications like pocket calculators. Its electrical output power is very low. But, recently some innovations made them more applicable one by using stacking technique. In this method several amorphous silicon solar layers are combined. By stacking solar cells into multiple layers, they can capture more sunlight and can produce more electricity.This technique gives more efficiency rate, typically around 6-8% more.

|

|

Plasma deposited amorphous silicon contains a significant percentage of hydrogen atom bonded into the amorphous silicon structure. This innovation helps to integrate the application of amorphous silicon panels. Other than silicon; gallium arsenide (Ga-As), copper-indium-diselenide (CuInSe2) and cadmium-telluride (CdTe) are under development. These exotic materials gives more efficiency and more interesting properties. Amorphous Silica can be made much thinner than other panels, which make them more flexible in use. Main advantage of this solar panels is that it can be deposited at very low temperature, as low as 75 degrees Celsius. It has great potential because one day it becomes cheaper than mono and polycrystalline solar cells. It can work even in bad lighting conditions and will not affect any shading issues. Wide ranges of manufacturer of amorphous silicon panels are available in the world. Du Pont Apollo, QS Solar, Sungen, Bosch, Moser Baer, China Ningabo star solar are the main .

Copper Indium Gallium Selenide Solar Cells

Copper indium gallium selenide is a semiconductor used for manufacturing solar cells. The glass or plastic backing has a layer of CIGS absorber deposited on it and electrodes are placed in the front and back so as to collect the current. The absorption coefficient is high for the material and sunlight is absorbed strongly. These devices manufactured with CIGS falls under thin-film solar panels category. The efficiency of CIGS is high when compared to other thin-film solar panels. The efficiency has reached an all-time record of 20.8% when compared to silicon solar panel with 20.4%.

The device structure of the CIGS photovoltaic cells consist of a substrate with soda lime glass. Just above the glass substrate, molybdenum layer is deposited which acts as a back contact. The Mo layer helps to reflect most of the unabsorbed light to the CIGS absorber layer. Above the absorber layer, the CdS and ZnO layer exist.

Global Solar Energy, Honda Soltec, Ascent Solar Technologies, DayStar Technologies, HelioVolt, International Solar Electric Technology, Nanosolar (printed electronics), SoloPower etc. are some companies that manufacture these solar cells.

Cadium Telluride (CdTe) Solar Cells

This type of solar cell is a thin film of cadmium telluride, originally a semiconductor layer which absorbs sunlight and converts it to electricity. This type of thin-film solar panels will replace crystalline silicon solar panels in case of cheapness. This kind of solar panels are having an upper hand in the ecological circles as this gives solution to many of the ecological issues including changes in the climate, scarcity of water and energy security.This technology is nowadays considered as the most efficient technology in terms of large scale commercial installations on rooftop or ground mount applications. These solar panels has the smallest carbon footprint, energy feedback is faster and energy security in terms of life-cycle basis and is now the second largest material in the solar cell production after silicon.General Electric has come up with solar panels with 19.6% conversion efficiency and First Solar Inc. has a record breaking conversion efficiency of 20.4%.

The advantages of CdTe solar panels over silicon-based panels include:

The major disadvantages of CdTe solar panels are:

Hybrid Panel

A hybrid panel with hybrid solar cells usually combines the advantages of both organic and inorganic semiconductors. The solar cells used in the panel can be of Polymer–nanoparticle composite, Carbon nanotubes, Dye-sensitized and Nanostructured inorganic types. Generally, the hybrid panels have the ability to generate 10% more electricity than conventional crystalline silicon solar panels.

Hybrid Panels are considered to be more expensive than mono or polycrystalline panels. Always, it is better not to choose hybrid solar panels if there is space on your roof to fit the same amount of power with crystalline panels. This is because; we will be just paying more to generate the same amount of electricity with crystalline panels. In commercial applications, 10-18% efficiency is the maximum that can be achieved with the panel.

The main manufacturer of hybrid panels is Panasonic (formerly Sanyo). Panasonic Hybrid Panels use the Heterojunction with Intrinsic Thin layer (HIT) technology. Through this technology, each hybrid solar cell in the panel combines a thin crystalline silicon wafer coated with amorphous silicon The extra amorphous layer here extracts more energy from the sunlight, particularly in medium light conditions. These are the efficient panels available and they take up the least space on our roof. Also, they can produce more power per square meter than other PV panels. Rack mounted installation method is used generally by Panasonic HIT-N240SE10 module

| Table 3: Specifications of a type of Hybrid Solar Panel | |

|

|

ALL Black Solar Panels

‘All Black’ solar panels usually use monocrystalline silicon cells laminated with black back sheet and framed with black anodized aluminum. The black frames and black backing helps to obtain a better appearance. On dark color plain tile roofs, these panels look really great. But the problem with black backing is that, black absorbs light from the sun which means that some of the sunlight will not get reflected back onto the cells. Also, the panels will get hotter. Generally, it is said that solar cells are more efficient when they are cooler, so the panels with black backs will surely perform less effectively than the ones with white backing. Blending well with the existing roof materials is one of the advantage of this panel. Through this advantage, damage during installation can be avoided.

“Pay more and generate less electricity” is one of the disadvantage of this panel. Generally, on grid and off grid residential roof tops, solar power stations, on grid and off grid industrial roof tops and other on – and off grid applications can use this panel for better appearance or aesthetic value. “Honeywell’ recently has introduced ‘PowerShield Cool Black’, a backsheet that can keep black panels cool, efficient and durable with surroundings. Canadian Solar, Trina Solar, Sharp etc. are some of its manufactures.

| Table 4:Specifications of a type of All Black Solar Panel | |

|

|

String Ribbon Silicon Cells

String Ribbon Solar cells is a form of polycrystalline silicon cell that is used as photovoltaic cells for the production of electricity from solar energy. String ribbon solar cells are manufactured by a process in which, wires that are temperature-resistant are pulled through molten form of silicon to form very thin multi-crystalline ribbons of silicon crystals. The ribbons obtained are cut into proper lengths followed by treating the ribbons by traditional process to get solar cells. String ribbon solar cells use half the silicon when compared to other crystalline silicon solar panels. The manufacturing costs rises with the amount of silicon being used in the process. It accounts to about 50% of the manufacturing cost and silicon is regarded as waste and discarded at the sawing stage of the manufacturing process. String ribbon process avoids this wastage and gets silicon wafers of approximate dimensions.

These types of solar cells converts less amount of solar energy to electricity, that is, approx. 13-14% , when compared to 15-16% conversion in case of other wafer technology. In research scenario, the efficiency has reached 18.3% for string ribbon solar wafers and in case of other wafer technologies it is 25%, which are not achieved in case of commercial applications.

Depending on the thickness, not every string ribbon solar strips can be directly processed as a solar cell. This type of cells has the lowest space-efficiency when compared to the crystalline based panels. In case of string ribbon solar cell, the requirement of heat is high for manufacturing process so energy costs are increased. This increase in energy will subsidize the decrease in manufacturing cost due to low amount of silicon usage.

String Ribbon Solar cells are mainly manufactured by Evergreen Solar Company, an American firm, currently bankrupt. These solar panels provide higher strength with wind and withstand snow loads. There is a wide range of mounting options. The features of solar panels manufactured by this firm include over 90% field performance ratings, -0/+5W power tolerance, within 12 months there will be energy payback, double-walled, high strength frame etc.

BIPV systems are solar power generation modules integrated directly into the building in the place of ordinary building materials (such as window overhangs, roofing, skylights and facades). Today, Building Integrated Photovoltaics (BIPV) is becoming the fastest growing segment of the solar industry. These systems can be applied after or during the construction of buildings. Besides electricity generation, a BIPV module provides other functionalities like safety, thermal insulation, aesthetical integration, safety etc. to the building envelope.

The basic building block of BIPV technology is a PV module. Solar cells are assembled to form a module, and modules are wired together to form a site-specific array. The solar cells can be monocrystalline, polycrystalline or thin film type. Usually, the BIPV modules are ideal for roofs, facades and skylights. There are three major types of BIPV that may be considered for integration into buildings. They are Glazing (glass) and laminates, solar roof tiles and cladding for building envelopes.

BIPV systems usually have lower overall costs than other solar systems which require separate mounting systems. These BIPV modules are established in countries like Japan and Korea and now coming up in China, Taiwan, Singapore and rest of the world. Cost of BIPV depends generally on the type of system being implemented (pitched or flat roof, façade or glazing) and the technology used for manufacturing it. According to the National Institute of Building Sciences ‘Whole Building Design Guide (WBDG)’, current manufacturers and suppliers for these types of systems include Atlantis USA Sunslates, bp solar, SolarFrameWorks Co., RWE SCHOTT Solar, Energy Photovoltaics, Inc., and UNI-SOLAR.

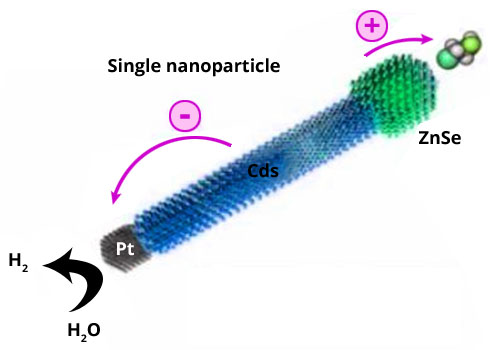

Nanocrystal Solar Cell

Solar cells that consist of a layer of substrate that is coated with selected nanocrystals: copper indium gallium seleneide (CIGS), cadmium telluride (CdTe) or silicon. Spin-coating is the process involved in the production of thin-film nanocrystals. Quantum dot solar cell is one type of nanocrystal solar cell. The production process involves a flat substrate on to which a quantum dot solution is placed and rotated at high speed. On rotation, spreading out of solution happens uniformly and spinning of substrate is done so that uniform thickness is obtained. The researches on nanocrystals are still on its infant mode with advantages like flexibility, cheaper costs, better efficiency, clean power etc.

Structure of the nanocrystal

A study at one of the top university has produced synthetic nanocrystals that are more reliable and durable in addition to which hydrogen gas is produced. The process replaces organic molecules with inorganic nanocrystals like zinc selenide, cadmium sulfide with a catalyst, platinum. Using of these nanocrystals makes it less prone to heat and ultra-violet radiation and also has protection from degradation problems. With addition to generation of electricity there is also hydrogen gas that is being produced that can fuel up the cell for the night.

Now the solar panels are also available in various colors. Isn’t it amazing? There are number of colors available in solar panels. They are available in gold, silver, bronze and many other shades. Just like the previous transparent and colorless solar panels, the colored solar panels are also environment friendly. The vivid appearance of these colored solar cells makes your building look vibrant.

Outstanding quality of surface

The surface quality of these solar panels is perfect. You do not feel any difference between a colorless solar cell and a colored solar cell. Now the solar panels colored or black are placed in a manner that they just look like a part of your building. Not only they become a part of your building but also enhance the beauty of your office or home. They can be fit in any place. There sizes are available. You can select them as per your requirement.

Efficiency

They are efficient in terms of working. As I have mentioned earlier that these solar panels can produce energy within no time. They will make sure that the energy you require for your system will be produced in a very short time. The God’s made creations when utilized by the human beings they become sharper and efficient. That is why the colored solar panels are used as an efficient way of getting solar power and converting it into electricity.

Cost effective

The colored solar panels are very much affordable. There is only one time expense of the fitting and little regular maintenance cost. Other than that they do not require any kind of large amount of investment. When you start using these solar panels, you will never have to pay a lot for the solar panels. The colorful and see-through solar cells were basically invented at the University of Michigan. They can be used one day as a colorful windows and shades and used to convert the solar energy into electricity. These cells, said to be the first semi transparent cell. They are the colored photovoltaic that has the power to widely broaden the use of the energy source like sun. This is what the scientists believed about the colored solar panels. According to them the colored solar panels are more beautiful and attractive. In near future they will be applicable to all parts of the world. They believe that they are not thinking about the solar panels at a very small area of research. It is a wide area to study and thus solar technology can be used widely and wisely. Today, some of the companies have introduced some colors in solar panels. Sooner all the companies will provide a wide variety of colored solar panels.

Uses of colored solar panels

Uses of colored solar panels

These colored solar panels can even be deployed in indoors. The original appearance of the building will be drastically changed when these solar panels are equipped in them. The typical black solar cells are able to absorb all types of wavelengths of the visible light. The colored cells are basically designed to broadcast or reflect colors. There are number of companies that are giving the original colored solar panels. It means that they provide non dyed solar cells. These original colored panels allow the images to be clear not blur. The process of manufacturing of solar panels does not require lots of effort. That is why they are cheap to buy and cheap to install. The colored solar panels can replace wall and windows. The market of dyed and sprayed colored solar panels has expanded in many countries so far. But the original colored panels have still a way to go. Near future will make these colored solar panels available for the consumers.The technology has transformed the lives of the common people. Similarly, the researchers and scientist are working in the field of solar panels that can be available in original varied colors. There is always a space for more research and hard working in all departments of life. Researchers are planning to make these colored solar panels more cost effective and efficient and thus working day and night on this phenomenon.

Transparent Solar Cells

Polymer solar cells (PSCs) have gathered immense amount of attention because of their basic advantages upon the usual solar cells. Best thing, about the transparent solar cell is that it has a high magnitude of conversion, which is about 10.6% more than the normal solar cells. This definitely portrays that polymer transparent solar cells are the promising candidate of the future, which have the ability to enlighten your house and offices in an eco-friendly and cost effective manner. Soon, these PSCs can be used on broader applications because of the potentials that they hold along with the devices that they use. Some of such broader applications have been made possible by the high performance visibly transparent devices, which work with the help of a building integrated photovoltaic (BIPV) along with a portable electronic device called PV chargers. There have been phenomenal works for creating visibly transparent and semitransparent PSCs. With the help of these solar cells that world can now have a brighter and better sustainable future for the planet.

There are several components that are required for the making of transparent solar cells. Some of them include conductors like metallic grinds, thin metal films, metal oxides, metal non-wires network, graphene and conducting polymers. These conductors are placed in-between photoactive layers so that the top electrode can appear transparent. Now, the PV materials that is present in the photoactive layer that gives the solar cells a transparent look, harvest almost 60% of the photons from the UV rays that fall near the Infrared region in the solar spectrum, and those photons that are present in the visible region get transmitted by the solar panels.

For a properly working transparent solar cell one is going to need a good polymer that has the ability to harvest optimum amount of photons. Somehow, scientists have uncovered that a 100% transparent solar cell is less effective compared to a semitransparent solar cell. The reason behind this is that, there is a high conversion of power that takes place and this conversion is utterly dependent upon the amount of photons that are absorbed by the solar panel. But, in polymeric film transparency there is a compromise between the amount of photons that are absorbed by the cell, and this limits the properties of PSCs. For instance, Poly (3-hexylthiophene) P3HT 6, 6-butyric acid methyl ester blend is the most widely used photoactive layer and this layer is semitransparent rather than being completely transparent. These PSCs hold great amount of absorption capacity and is even better than the transparent ones.

Till now, we have been only discussing that how transparent solar cell could not match up with the standards of semitransparent ones. But, is there any way that even they could correct this flaw? Well, for doing that one needs an ideal transparent conductor which will increase the photons absorption capacity of the solar cell. For this, the solar cell must have high level of transparency and low resistance so that it can obtain an effective processing system. One thing is noted here and that is the high conducting materials are not completely transparent. Such as the thermally evaporated thin films which have amazing conducting ability but are not transparent. This is where the solution process came for the rescue. The solution process- able materials can be easily processed so that they can be converted into a transparent film. Some of these amazing process-able conductors are carbon nanotubes, silver nanowires, and graphene.

In the near future the focus is on increasing the performance of the solar cells. To do this, scientist have stated to apply a thin coat of AgNWs on the photoactive layer which is an alcohol based sol-gel that will allow the photoactive layer to function in a better way. So, in the near future we will be able to explore a better and well developed transparent solar cell that will take the entire concept of transparent cells to a whole new level.

Residential and industrial sectors are the main users of solar energy. In residential sectors, solar energy can be used for generating electricity using the solar photovoltaic technology. In the form of solar water heaters, water heating is also possible. For cooking applications, nowadays the solar cookers are gaining more popularity. In industrial sectors, Sun’s thermal energy can be used to supply power.

Today, Solar energy is good to power radio and TV stations, lighthouse and warning lights for aircraft. Solar cars, remote areas and even swimming pools can use the solar photovoltaic technology. Agriculture and all horticulture sectors can use the solar energy for the efficient productivity. Last but not the least, solar energy have endless applications in the world and in the near future we can expect many new advancements in the solar technology.

Sections